On this Page

Frequently Asked Questions

Click on the questions below to see answers.

Food Safety should not be a worry necessarily, but should certainly be taken into consideration anytime that any foods are being either sold or provided for public consumption. At direct markets, food can become contaminated with foodborne pathogens and cause foodborne illness in a variety of ways. As a producer, you should be aware of the different avenues for contamination, and be sure to try to prevent contamination from occurring. Your #1 priority as a food producer is to prevent and lessen the chances the consumer gets sick from your product.

- Sick or unclear workers

- Contaminated agricultural and wash water

- Untreated, or unsafe soil amendments, like manure or compost

- Contact with both wild and domestic animals

- Contact with contaminated tools, equipment, facilities

- Improper hygiene and sanitation

Washing produce is controversial when it comes to the question, does washing make my produce safer? It is recommended to wash produce in clean, drinkable water to remove any excess dirt, soil, and other contaminants. However, the research shows that if pathogens are present on the food, washing alone will not remove them! This is why prevention of exposure to pathogens is the best defense. Good Agricultural Practices should be used to help prevent contamination from bacterial, chemical, and physical contaminants during both pre and post harvest handling.

In many situations, it is product dependent. Reusing unclean containers can lead to cross contaminating clean product with a previously contaminated product. Some containers are cleanable and able to be sanitized; these are the best containers to use for food. Containers such as wood crates, that have the ability to absorb contaminants, can lead to a source of contamination. Therefore, it is recommended to use containers that cannot be properly cleaned and sanitized only one time.

-

- Leaves (lettuce, spinach, etc.) have very tiny (almost invisible) openings for gas exchange called stomata. The plant takes in carbon dioxide and gives off oxygen and water vapor through these openings. At these openings, water can accumulate. If the water contains foodborne pathogens, they can attach to these small openings, where they are then protected and penetrate inside the plant tissue.

Tomatoes have a porous stem scar where, under the right conditions, pathogens (if present on the surface of the tomato, or in the wash water) can move into the pulp of the fruit, where they can grow and are protected from washing.

Tomatoes have a porous stem scar where, under the right conditions, pathogens (if present on the surface of the tomato, or in the wash water) can move into the pulp of the fruit, where they can grow and are protected from washing.

-

- Cantaloupes are a great example of a fruit that has a stem scar and also has a netted rind. Because of these features, cantaloupes can be problematic by allowing contaminated water to enter into the fruit. In fact, this is one reason why when cutting a cantaloupe, you may have heard about making sure to be careful of not exposing any dirt on the surface of the rind to the inside with a knife.

Displaying and packing in wood is riskier than other surfaces, if it is possible to replace wooden food contact surfaces with a material that is non-porous such as plastic or stainless steel, you can decrease your risk of cross contamination. There are alternatives however, such as covering wood surfaces with clean plastic sheeting, or dishtowels or other fabric that can be cleaned and sanitized between uses. There are also forms of food safe paint that can be applied to seal wood surfaces, but those surfaces must be cleaned thoroughly and the paint surface must be maintained to prevent areas where contamination can occur.

Broccoli should be cooled with packed ice immediately after harvest. To maintain best quality product the broccoli should remain on ice to sell to consumers. Whenever using ice, make sure that the water used to make the ice is a potable source, even if you are purchasing from a commercial vendor. If you are making your own ice, it is also important to remember to keep any ice trays or ice machines/scoops regularly cleaned and sanitized and handled in such a way to prevent cross-contamination.

Growing and selling of whole produce generally does not require any special handling, but when you cut a product such as melon, it falls under the category of foods called: Time and Temperature Controlled for Safety or TCS foods. Food in this category require temperature control because of the risk of microorganism growth. Cut melon should be kept at a temperature of 41 ºF or lower. This temperature must be maintained for cut samples of fruit and vegetables as well. This can be done at the market by placing cut samples in single-serve containers and keeping them in a cooler with potable ice. Make sure that any utensils used for cutting the fruit area cleaned and sanitized prior to use.

Generally, samples that are given away at a market do not fall under regulation because they are not for sale. However, there are some best practices for vendors to follow when offering samples to the public to prevent illnesses. The best practice for vendors would be for them to prepare their samples at home and package in individual single serving sizes for customers to pick up without having to touch food contact surfaces. If the produce will be cut and served while at the market, it is recommended that the vendor follow the same guidelines for vendors that are preparing food at the market. Listed below:

What must be done when serving samples:

- There should be the ability to wash serving utensils and hands on site

- Utensils should have separate bins in which they can be washed, rinsed and sanitized to help avoid cross contamination between different products and prevent the use of any soiled serving equipment

- Not only must a hand washing station be available, but good hygiene should be practice by all serving samples

- Even with clean hands, avoid barehand contact with ready to eat samples using clean utensils and items like gloves, and serving paper.

- Avoid allowing customers the opportunity to touch product that is intended to sell to some one else.

- Consider protection from weather and outdoor elements using tents, canopies, umbrellas, etc. Also cover samples once they are prepared to avoid contact with insects and other forms of contamination.

- Hold all samples in proper containers at the proper temperatures.

- Hot Holding is 135°F or higher and Cold Holding is 41°F or lower, make sure to monitor temperatures using a calibrated thermometer

- When using ice, melted ice water should be changed out frequently, to prevent contact of contaminated water with food.

- Hold all samples in proper containers at the proper temperatures.

When leafy greens like lettuce are cut, the exterior portion of the leaf are exposed to the nutrients from the inside of the leaf. Microorganisms can use these nutrients to grow. It is for this reason cut leafy greens are considered a Time and Temperature Controlled for Safety or TCS food. Food in this category require temperature control because of the risk of microorganism growth. Generally, the harvest cut for lettuce is not included in the definition of “cut leafy greens”; however, further cutting of the leaf to make chopped or cut salad mixes would then consider the produce to be “value added” and it would be required to be held below 41 °F.

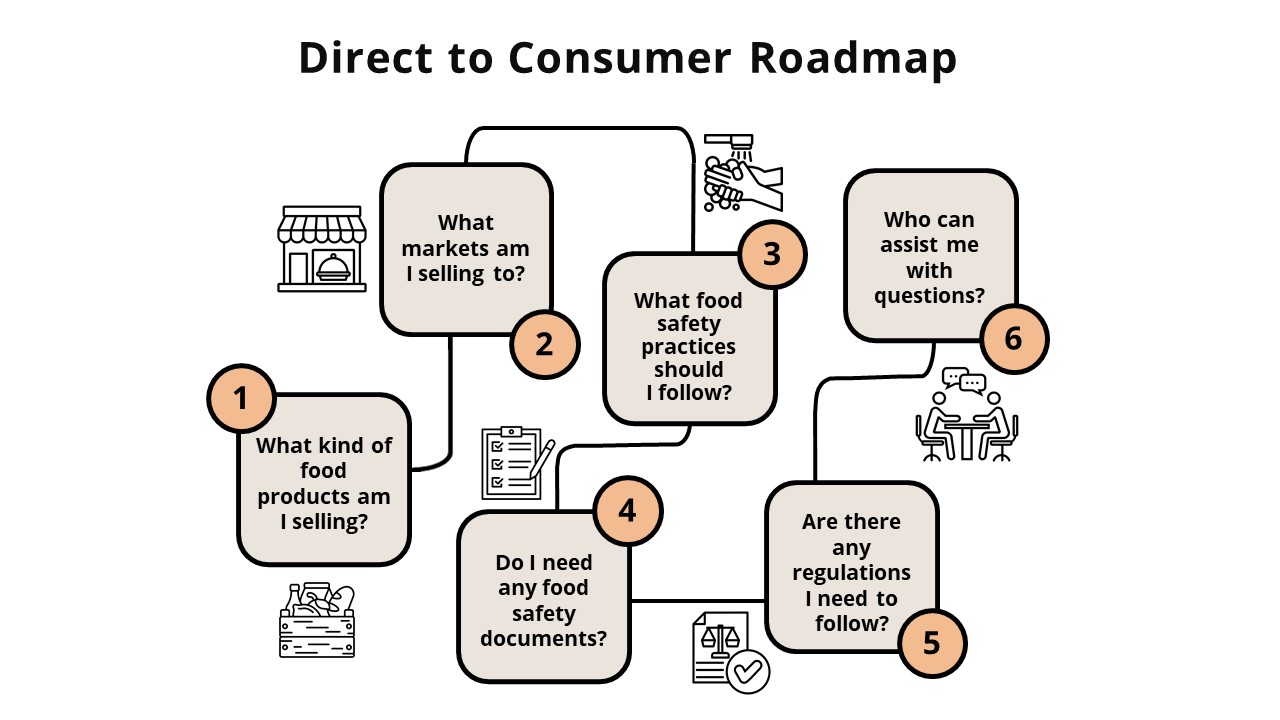

Direct Market Food Safety Resources

Going to Market

An overview guide to selling raw, processed and prepared food products at farmers’ markets, stores and roadside stands.

Enhancing the Safety of Locally Prepared Foods

Often understanding the steps needed to prepare foods for sale in the direct market such as Farmers Markets can be complex. Regulations and steps for producing foods safely can vary greatly depending on the food product. These factsheets provide great information related to what you need to know to sell the following food products:

- Acidified Foods

- Baked Goods

- Dehydrated Foods

- Fermented Vegetables

- Honey

- Jams, Preserves, Jellies, and Fruit Butters

- Kombucha

- Labeling Foods for Sale

- Maple Syrup

- Meat and Poultry

- Packaged Meals (Refrigerated/Frozen)

- Pet Foods or Pet Treats

- Refrigerated Dips, Spreads, Dressings, and Salads

- Samples

- Shell Eggs